Global Commutator Manufacturer

Superior Commutator Manufacturing | V-Bound Commutators, Glass Banded Commutators, & Shrink Commutators

Electric Materials has been a leader in manufacturing commutator segments, v-bound commutators, glass banded commutators, and shrink commutators for various industrial applications for over 100 years. Our expertise is recognized throughout the world, and our commutators are in service in some of the most demanding applications in the rail, steel mill, and naval industry. Many advantages to choosing to work with EM over other commutator manufacturing companies include, but are not limited to:

- Complete start-to-finish manufacturing capabilities for commutator rings, bars, and other designs

- Experts in commutator rebuilding and the refilling of existing commutators

- Consistent, reliable, and high-quality products such as collector rings

- Assemblies processed to the applicable engineering instruction resulting in a finished product that is of the highest quality

Commutator Design

Whether you require a commutator segment based on an existing commutator model or a customized commutator design, our engineers can create a component that meets your exact specifications. We have in-depth design capabilities and are registered to IS0 9001:2015.

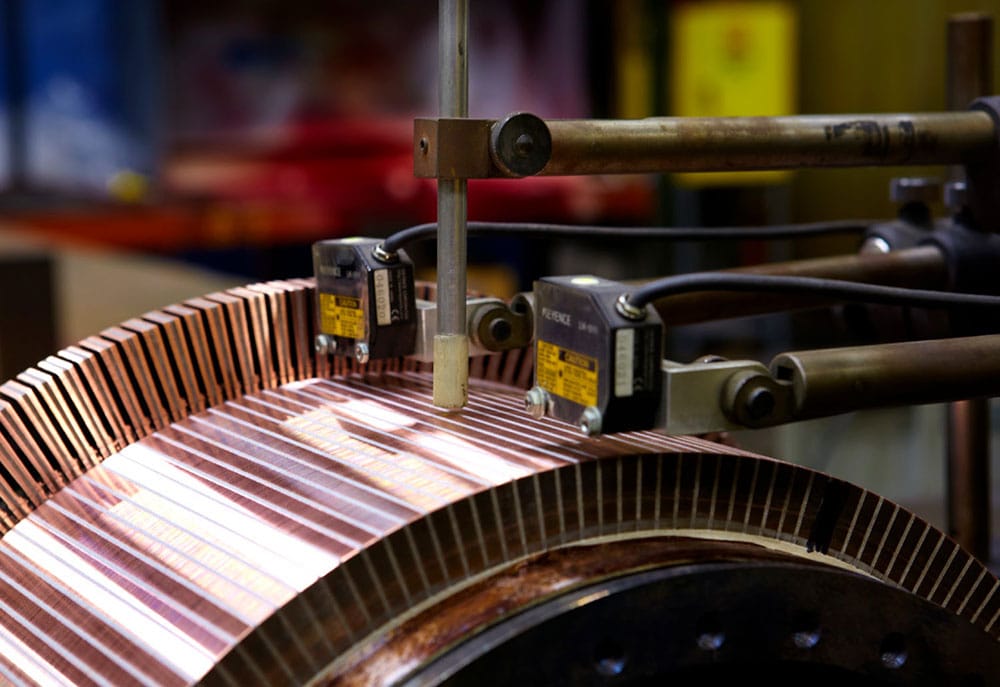

Commutator Segment Production

Electric Materials is capable of manufacturing commutators built to existing model specifications as well as producing customized commutators with brand new steel commutator parts. Some standard commutator types Electric Materials readily delivers are:

- V-Ring commutators

- Glass band commutators

- Shrink ring commutators

EM also offers wire banded assemblies, commutator bar packs, and mica v-rings designed and produced to your requirements.

V-Bound Commutator Manufcaturing

As a commutator manufacturer, Electric Materials produces numerous types for your specific needs, including V-bound commutators. V-bound commutators are named for the internal v-shaped configuration that retains the copper bars and mica segments. The copper bar and mica segment pack are bored with a v-shaped groove on each end of the pack. The mica v-rings are used as electrical insulation between the copper segments and the steel parts. The most common angles for these commutators are 3 degrees on the outer angle and 30 degrees on the inner angle.

One of the advantages of a V-bound commutator is that it can be taken apart to replace copper, replace mica v-rings, or fix obvious electrical problems easier than other styles. Depending on the design of the unit, some V-bound commutators can be re-insulated. This involves repairing the mica segments between the copper bars, replacing the mica v-rings, and re-using the copper bars.

Glass Banded Commutator Production

Glass band commutators are named for the glass bands that are used to retain the copper bars and mica segments. The bands are applied in two or more grooves that have been machined into the outer diameter of the copper bars. The glass bands consist of an electrical grade tape comprised of high tensile strength parallel glass yarns bonded with thermosetting resins. The tape is applied under tension and cured in an oven.

The main advantage to using a glass banded commutator is that a bounded glass commutator can be retained in multiple locations over the entire length of the commutator bar. This results in higher stability for units with longer bars as compared to v-bound commutators that only retain on each end of the bar. Some other advantages to glass banded commutators include:

-

- Lightweight, as less steel is required

- A smaller profile (depending on the design of the steel barrel

- Less likely to be moved or damaged by a bump due to the inner diameter support by the barrel and barrel insulation

Electric Materials designs and manufactures high-quality glass band commutators for numerous industrial industries and applications.

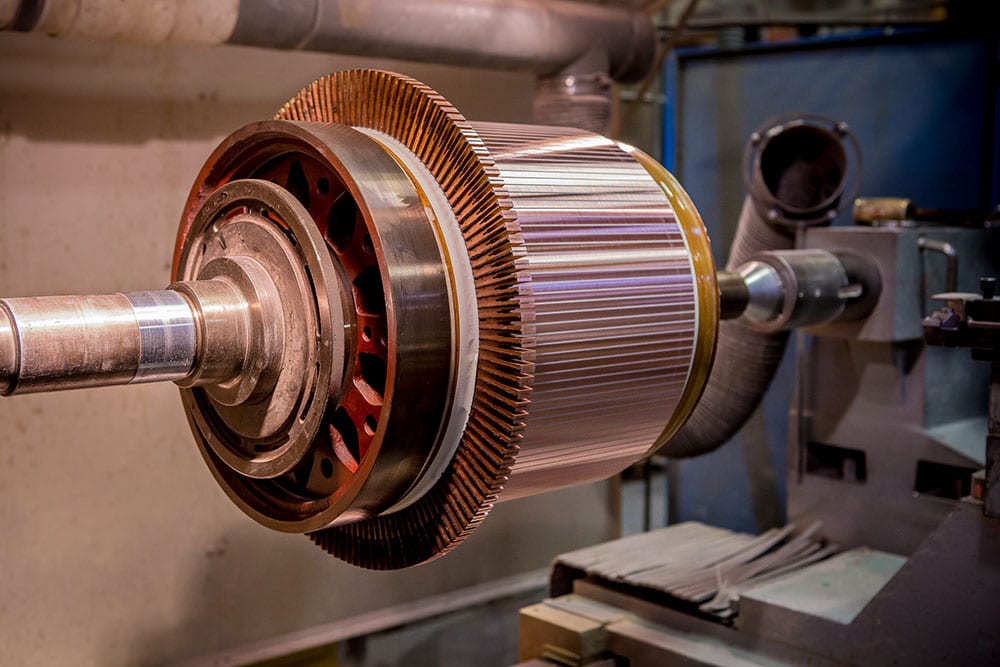

External & Internal Shrink Ring Commutators

Steel shrink ring commutators are named for the steel rings that are used to retain the copper bar and segment mica pack. They are sometimes called Dynamometer or Exciter commutators which refer to how the commutator is used. There are two primary types of shrink ring commutators that are used for different reasons, external shrink rings and internal shrink rings. Both styles rely on the interference fit on the inner diameter of the steel rings to maintain the stability of the copper bars and mica segment packs.

External Shrink Ring Commutator

External shrink ring commutators are used for applications that require extremely high RPMs. This results in stress values that would be too high for other commutator designs. This style is more expensive than v-bound or glass band commutators due to the higher material costs and the additional labor required to assemble.

Internal Shrink Ring Commutator

Internal shrink ring commutators also utilize high-strength forged ring material to retain the segment pack, are more expensive than V-bound or glass band units, and are very difficult (if not impossible) to take it apart to replace insulation or clear any internal shorts. Due to lower cost and ease of repair, many internal shrink ring commutators are converted to the V-bound style.

For exceptional quality, performance, longevity, mechanical, and electrical integrity, trust Electric Materials to manufacture your commutator rings.

Copper Alloy Collector Rings and Slip Rings

Collector rings, also commonly referred to as slip rings or rotary joints, are electromechanical devices used to transfer a signal or electrical power through a rotating assembly. Some applications for collector rings include wind turbines, alternators, air conditioning systems, and electric generators. Electric Materials manufacturers customized copper alloy slip rings for your specific needs.

Commutator Rebuilding and Refilling Services

Electric Materials also specializes in the rebuilding and refilling of existing commutators rings, bars, and more. Units are disassembled and rebuilt with new copper using the same quality assurance processes applied to new commutators. Whether it is a commutator ring repair or collector rings, we assure you it will be right the first time, on time, every time. Our extensive database of commutator specifications and history ensures that your unit is rebuilt to meet the operational demands of the final application.

Commutator Manufacturing FAQ

WHAT IS COMPRESSION SEASONING?

“Compression Seasoning” is the standard process for building a commutator. Many commutator manufacturers also refer to it as “static seasoning.” The standard process for building a commutator consists of a series of compressions and bakes at different times throughout the machining of the copper and mica pack. The formula for the number of bakes, bake times, and compression tonnage is determined by the commutator size, application, and speed that it will be operating at. For over 90 years, Electric Materials has developed “static seasoning” processes that lead to unmatched quality and performance in our commutators.

WHAT IS SPIN SEASONING?

Spin seasoning is the test done after the commutator has been statically seasoned or “compression seasoned”. During this test, Electric Materials will spin the commutator at or above the operating speed while applying heat. It is then cooled and the runout is recorded. This extra process ensures your commutator is stable and can withstand the operating speed. The spin speed is either supplied by the customer or determined by our engineering team based on the supplied operating speed and stress analysis. The majority of OEMs require their commutators to be spin seasoned.

BESIDES SPIN SEASONING, DOES EM OFFER OTHER TESTING OR MEASUREMENTS TO ENSURE THE TIGHTNESS OF THE COMMUTATORS?

Yes, Electric Materials offers profiling services. Profiling is done in line with the spin seasoning process. The profiling process will record any bar movement at multiple locations along the brush surface after the commutator has been spun. Measurements are taken before and after the spin cycle. In most cases, our customers set the parameters of our profiling process.

HOW DO YOU MANUFACTURE COMMUTATOR BARS?

Electric Materials extrudes copper on one of our two extrusion presses and then we cold draw it to finish size. We have the ability to finish draw to a .0005” tolerance. During our cold drawing process, the commutator bar is cold worked to obtain the appropriate mechanical properties it requires to build a stable commutator. OEMs require commutator bars to be drawn to size to achieve these tight tolerances and mechanical properties.

WHAT IS ELECTRIC MATERIALS EXPERTISE WITH COMMUTATORS?

Electric Materials has been building commutators for OEMs for over 90 years. We have built for many OEMs including GE, WHSE, and Reliance. From working with many of these OEMs, we have built a large database of OEM drawings that we can use to assist us in manufacturing new and old designs.

CAN YOU MANUFACTURE MICA V-RINGS WITHOUT HAVING A WHOLE COMMUTATOR?

Yes, Electric Materials has a very large selection of Mica V-ring molds which we can use to make one-piece or sectional mica v-rings without copper or steel components. Our molds range from just under 2” to 121” in gauge diameter.